Castors are one of the key elements of a roll container. While choosing the optimal castors the following factors should be considered: floor surface, roll container workload and operating environment. Operating life and comfort of usage in great measure depend on proper attention to the castors choice.

Below you can find information on castors constitutive elements.

|

Wheel.

Polyamide, steel, polyurethane, polypropylene and rubber are mostly used for wheels center production. When wheel tread is mostly made of rubber or polyurethane. Wheel can also be monolithic (both wheel center and its tread made from the same material).

Wheels with polyamide tread are robust, resistant to abrasive wear, load impact and corrosion. Easy movement on even surfaces.

|

Wheels with polyurethane tread are resistant to wear and corrosion, ensure easy movement on even surfaces. This type of wheels is well suitable for usage in manufactories with poured concrete floors, tiled floors, asphalt, but it is to be noted that this wheels are not soft-running.

|

If the roll container is mostly to be used on hardwood floors, tiles or ground then polypropylene wheels with rubber or polyurethane tread should be considered.

|

This type of wheels ensures smooth and quiet running.Most noiseless operations, high load capacity and endurance are guaranteed when polyamide or steel wheels with polyurethane tread are used, though their price range is higher.

|

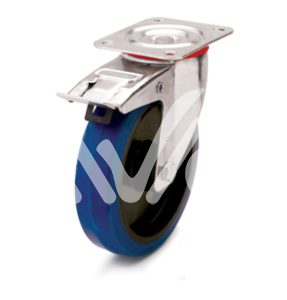

Castor.

Castor consists of wheel and housing. Castors can be fixed or swivel. Fixed castors cannot run on an axis, they keep hold of the set direction of a roll container. Swivel castors easily run on its axis that eases control over a roll container and ensures its maneuverability. If necessary, brakes can be installed on the castors.

|

If roll container is to be used for textile or cloth deliveries then it is possible to protect wheels with treadguards that are fitted on both sides of the axis.

Bearing.

Three types of bearings are used in roll containers castors.

If roll container is not to be used very often and you don’t require fast speed operations then the most cost efficient options – plain bearing.

|

Roller bearing has average endurance and noise characteristics.

|

If roll container is to be extensively used with heavy loads then ball bearing would be the best choice.

|

Castors production is arranged in many countries, the biggest manufacturers are located in Poland, Czech Republic, Italy, Germany, USA and China. Quality-price ratio depends on castor type and origin country.

Our specialists will be happy to discuss your requirements and help you choose the best suited type of castors for the roll container.